What is PIBSA?

Time:

2025-08-15

What is PIBSA?

Introduction to PIBSA

PIBSA is short for Polyisobutenyl Succinic Anhydride, a chemical compound widely recognized for its ability to improve the performance of lubricants, fuels, and various industrial products. While it might sound like something found only in a laboratory, PIBSA is actually a workhorse ingredient in sectors ranging from automotive engineering to oil and gas production.

Whether it’s PIBSA automotive driveline additives keeping your vehicle running smoothly or PIBSA emulsifier compounds ensuring industrial fluids mix correctly, this versatile additive plays a quiet yet crucial role in modern industry.

The Meaning of PIBSA

At its core, PIBSA refers to a compound formed by combining polyisobutylene (PIB) with maleic anhydride through a controlled reaction process. The resulting material has strong affinity for both oil and water phases, making it ideal as a dispersant, emulsifier, and protective additive.

This adaptability has made PIBSA essential in metalworking additives, oil & gas specialty additives, and even explosive products for mining and construction.

Why PIBSA is Important in Various Industries

PIBSA is valued for three main reasons:

Versatility – It can be tailored to different industries and purposes.

Performance Enhancement – Improves lubrication, fuel stability, and product shelf life.

Compatibility – Works well with other chemical additives, including detergents, anti-wear agents, and corrosion inhibitors.

The Chemical Nature of PIBSA

Understanding Polyisobutenyl Succinic Anhydride (PIBSA)

Polyisobutenyl succinic anhydride PIBSA and polyisobutylene succinic anhydride PIBSA are essentially the same, though the naming varies slightly based on chemical nomenclature. The long hydrocarbon chain from polyisobutylene makes PIBSA oil-soluble, while the succinic anhydride group allows further chemical modifications.

How PIBSA is Derived from Polyisobutylene

The process involves reacting polyisobutylene with maleic anhydride under heat and pressure, producing a viscous liquid. Depending on the intended use, PIBSA process additives may be included to optimize the reaction yield and purity.

Key Properties of PIBSA

Physical and Chemical Characteristics

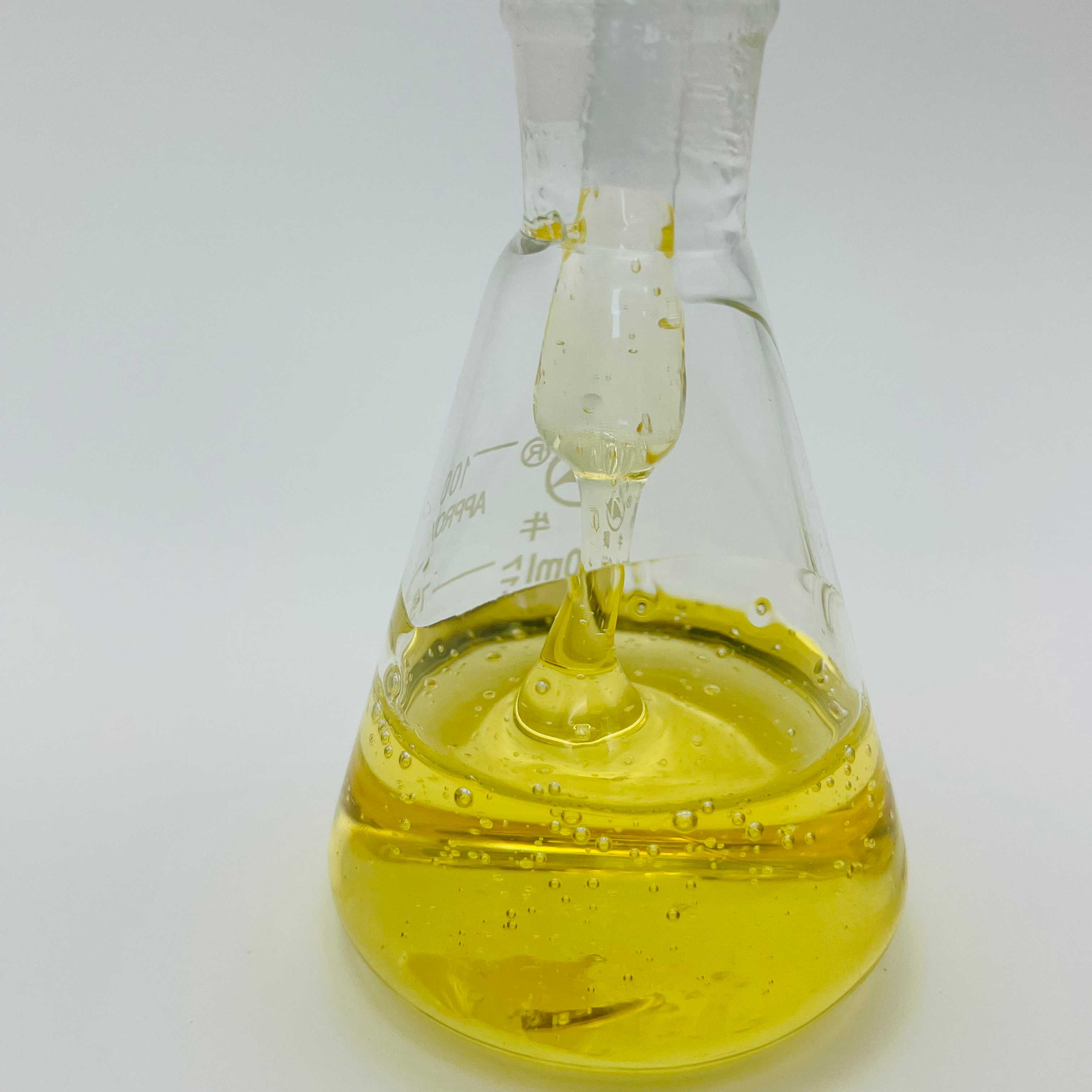

Appearance: Typically amber to brown viscous liquid

Solubility: Oil-soluble, limited water interaction unless chemically modified

Functionality: Acts as dispersant, emulsifier, and adhesion promoter

Solubility, Stability, and Compatibility

PIBSA blends easily with oils, fuels, and synthetic lubricants, making it an ideal choice for additive packages. Its chemical stability ensures long shelf life, especially in PIBSA oil & gas specialty additives where extreme conditions are common.

The PIBSA Manufacturing Process

PIBSA Process Additives and Their Role

Manufacturing pibsa isn’t just about mixing two chemicals together; it’s a carefully controlled reaction where PIBSA process additives are sometimes introduced to ensure a consistent product. These process aids help:

Control reaction speed and prevent unwanted side reactions.

Improve the purity of polyisobutenyl succinic anhydride PIBSA.

Enhance final product performance in downstream applications.

By fine-tuning these additives, manufacturers can create PIBSA optimized for very different roles — from PIBSA automotive driveline additives to PIBSA explosive products.

Reaction Steps in Producing PIBSA

The standard process involves:

Preparation of Polyisobutylene (PIB): A long-chain hydrocarbon polymer.

Reaction with Maleic Anhydride: Under controlled temperature and pressure, maleic anhydride attaches to the PIB chain.

Formation of PIBSA: The anhydride functional group is now available for further chemical modification or direct use.

Quality Control and Safety Considerations

Since pibsa chemical production involves reactive substances, safety protocols are vital. Strict quality checks ensure:

Consistent viscosity.

Correct succinic anhydride content.

Low impurities for better performance in pibsa dispersant or emulsifier applications.

PIBSA in Automotive Applications

PIBSA Automotive Driveline Additives

In automotive engineering, PIBSA automotive driveline additives help improve gear oil and transmission fluid performance. Their benefits include:

Improved lubrication for smoother gear shifts.

Reduced sludge formation by dispersing contaminants.

Extended component life by preventing wear and corrosion.

Benefits in Engine Oils and Lubricants

As a pibsa dispersant, it keeps soot, dirt, and oxidation byproducts evenly suspended in oil, preventing deposits in critical engine parts. This results in:

Cleaner pistons and valves.

More stable oil viscosity over time.

Better fuel economy due to reduced friction.

PIBSA in Oil & Gas Industry

PIBSA Oil & Gas Specialty Additives

In the oilfield sector, pibsa oil & gas specialty additives play an essential role in:

Pipeline cleanliness — dispersing sludge and preventing blockages.

Corrosion control — protecting metal surfaces in harsh environments.

Water-oil separation — aiding in crude oil processing.

Role as Dispersant and Corrosion Inhibitor

Polyisobutylene succinic PIBSA can be chemically modified into dispersant molecules that keep contaminants suspended in oil or fuel streams. It also forms a protective film on metal surfaces, reducing corrosion even under high pressure and temperature.

PIBSA as an Emulsifier

PIBSA Emulsifier for Industrial Fluids

As an emulsifier, pibsa emulsifier helps water and oil mix into stable blends. This is particularly important in:

Metalworking fluids.

Industrial cooling systems.

Agricultural oil-based sprays.

Benefits in Metalworking Fluids

When used as part of pibsa metalworking additives, PIBSA emulsifiers:

Ensure uniform coolant distribution.

Reduce tool wear during machining.

Improve surface finish on metals.

PIBSA in Metalworking Additives

How PIBSA Improves Machining Lubricants

PIBSA helps maintain stable lubricant emulsions, reducing breakdown under heat and pressure. This leads to:

Longer fluid life.

Less foaming in high-speed operations.

Better protection against rust.

Wear Reduction and Surface Protection

Pibsa chemical molecules create a thin, adherent layer on metal surfaces that minimizes wear, even during aggressive cutting operations.

PIBSA Dispersant Applications

Keeping Contaminants Suspended in Fluids

A core strength of pibsa dispersant additives is their ability to bind to small particles and keep them from settling. This prevents:

Sludge in engines.

Sediment in fuel tanks.

Blockages in hydraulic systems.

Applications in Automotive and Marine Engines

Whether in cars, trucks, or marine vessels, PIBSA dispersants help maintain performance in challenging operating environments, including extended idling and high-load conditions.

PIBSA in Explosive Products

Role in

In mining and construction, pibsa explosive products are used in water-in-oil emulsions to create stable, high-energy explosives. The PIBSA component ensures:

Long-term emulsion stability.

Consistent detonation performance.

Stability and Performance Factors

The emulsifying action of polyisobutenyl succinic anhydride PIBSA keeps the fuel and oxidizer phases from separating, which is critical for safety and efficiency in explosives.

FAQs

1. What is PIBSA used for?

PIBSA is used as a dispersant, emulsifier, and lubricant additive in automotive, industrial, oil & gas, and explosive applications.

2. Is PIBSA the same as polyisobutylene succinic anhydride?

Yes. Both names refer to the same compound, though the spelling may vary.

3. How is PIBSA made?

It’s produced by reacting polyisobutylene with maleic anhydride under controlled conditions.

4. Is PIBSA hazardous?

While generally stable, PIBSA should be handled with care and according to safety guidelines.

5. Can PIBSA be used in both automotive and industrial applications?

Absolutely — its versatility allows it to be adapted to many environments.

6. What industries rely most on PIBSA?

Automotive, oil & gas, metalworking, and explosives manufacturing are among the top users.

Previous page

Previous page

PRODUCTS CENTER

MORE BLOG

2025-08-15

2025-08-11

2025-08-09

2025-08-08

CheMost

CheMost Additives CO.,LTD

ADDRESS: CheMost Additives CO.,LTD, Jinzhou city, Liaoning provice, China

To learn more about CheMost, please click the button to contact us anytime.

Get product catalogCopyright© 2025 CheMost Additives CO.,LTD

Website:300.cn jinzhou.300.cn | SEO | Privacy Policy