Polyisobutylene - adhesive additives

Time:

2025-09-17

Polyisobutylene: Adhesive Additives in Lubricants

Understanding PIB’s Role in Tackiness, Sealants, and Adhesives

Introduction

Polyisobutylene (PIB) is a really useful polymer. It's a key ingredient in making different kinds of adhesives, lubes, and sealants. When you add PIB to other products, it makes them work even better. You can find it in cars, factories, and even things you use around the house. This article takes a look at what PIB is all about, like what it’s made of, the different kinds there are, and how it's used as an adhesive additive in lubes. We'll focus on things like its molecular weight, how sticky it is, and how well it works as a sealant.

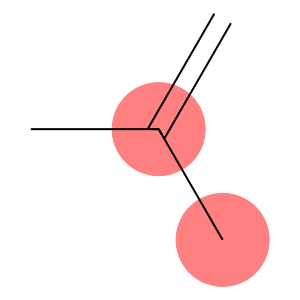

What is Polyisobutylene?

Polyisobutylene, or PIB, is a man-made stuff that starts from isobutylene. Because it doesn't react easily with other stuff, doesn't evaporate much, and flows well when it's cold, it's used a lot in glues, oils, and sealants. You can mostly find PIB in two forms: very reactive and not so reactive. Because of how PIB molecules are shaped, it works well as a glue because it's sticky, can be made thick or thin, and stays strong even when pulled hard

Types of Polyisobutylene

Polyisobutylene comes in different forms based on its molecular weight and activity level. The main types include:

- Highly Active Polyisobutylene: This form has a lower molecular weight and is used for applications requiring high tackiness and fast bonding. It is highly soluble and provides excellent adhesive properties.

- Low Activity Polyisobutylene: With a higher molecular weight, this form of PIB is often used in sealants and lubricants, where long-lasting consistency and better resistance to environmental factors are needed.

PIB in Lubricants

Polyisobutylene is a common ingredient in the lubricant biz. It's used to make oil sticky and work better. Because it makes base oils more slippery, stickier, and prevents parts from wearing down, it's key for cars and factory machines. PIB helps cut down on friction and keeps machines running smoothly by creating a strong layer of lube.

PIB’s Effect on Molecular Weight

How heavy a polyisobutylene (PIB) molecule is matters for what it's good for. Lighter PIB molecules usually stick faster and better. Heavier ones are used when you need something that lasts longer and stays put. How heavy the PIB molecule is impacts how thick it is, how well it holds up under stress, and how well it keeps its form even when things change.

PIB as a Sealant Additive

Polyisobutylene is also widely used in the formulation of sealants. Its high molecular weight variant is particularly effective in providing long-lasting, flexible seals that resist environmental stress, such as temperature fluctuations, moisture, and mechanical stress. PIB-based sealants are used in industries such as automotive, construction, and electronics, where reliable sealing is critical to the performance of products.

Applications of Polyisobutylene in Adhesives

Polyisobutylene is widely used in adhesive formulations due to its excellent tackiness, viscosity control, and ability to bond strongly to various surfaces. Some of the key applications include:

- Pressure-Sensitive Adhesives (PSAs): PIB is often used in PSAs, which are adhesives that form bonds without requiring heat or solvent activation. They are commonly found in products such as tapes, labels, and medical adhesives.

- Hot-Melt Adhesives: In hot-melt adhesives, polyisobutylene helps improve the adhesion and bonding strength of the adhesive at high temperatures.

- Automotive Adhesives: PIB-based adhesives are used in automotive manufacturing to bond components such as trim, mirrors, and glass.

Advantages of Using Polyisobutylene as an Adhesive Additive

| Advantage | Explanation |

|---|---|

| Enhanced Tackiness | PIB significantly improves the adhesive’s ability to bond quickly and effectively without requiring additional heat or curing time. |

| Low Temperature Performance | PIB provides stability and fluidity at low temperatures, making it ideal for cold-weather applications. |

| Improved Durability | The high molecular weight of PIB-based adhesives offers excellent durability, resistance to wear, and flexibility over time. |

| Versatility |

Polyisobutylene can be tailored for various applications, from high-tack adhesives to long-lasting sealants and lubricants. |

FAQs

Q1: What makes Polyisobutylene ideal for use in adhesives?

Polyisobutylene’s high tackiness and ability to bond quickly without requiring heat make it perfect for pressure-sensitive and hot-melt adhesives.

Q2: How does PIB affect the molecular weight of a formulation?

The molecular weight of PIB affects its viscosity, tackiness, and shear stability. Lower molecular weight PIB enhances adhesion, while higher molecular weight PIB improves durability and resistance to wear.

Q3: Can polyisobutylene be used in both automotive and industrial adhesives?

Yes, PIB is commonly used in automotive adhesives for bonding components such as trim, mirrors, and glass, as well as in industrial adhesives for various manufacturing applications.

Q4: What is the difference between highly active and low activity polyisobutylene?

Highly active polyisobutylene has a lower molecular weight and is used in applications requiring fast bonding and high tackiness, while low activity polyisobutylene has a higher molecular weight and is used in sealants and lubricants for longer-lasting stability.

Q5: Is polyisobutylene safe to use in adhesives and lubricants?

Yes, polyisobutylene is considered safe for use in adhesives, lubricants, and sealants. However, as with all chemicals, it should be handled according to manufacturer safety guidelines.

Conclusion

Polyisobutylene (PIB) is good for adhesives, lubes, and sealants because it's sticky, controls thickness, and is stable. It works in many products, such as sticker glue and car sealants.

PIB makes things last longer and work better in cars, factories, or everyday items. If you know how PIB works, you can get the most out of it when making products.

Previous page

Next page

Previous page

Next page

PRODUCTS CENTER

MORE BLOG

2025-09-17

2025-09-15

2025-09-11

2025-09-08

2025-09-03

CheMost

CheMost Additives CO.,LTD

ADDRESS: CheMost Additives CO.,LTD, Jinzhou city, Liaoning provice, China

To learn more about CheMost, please click the button to contact us anytime.

Get product catalogCopyright© 2025 CheMost Additives CO.,LTD

Website:300.cn jinzhou.300.cn | SEO | Privacy Policy