What is Polyisobutylene?

Time:

2025-08-18

What is Polyisobutylene?

Introduction to Polyisobutylene (PIB)

Polyisobutylene, often call as PIB, is a versatile synthetic polymer, from the engine oil that keeps a car running smoothly to the adhesives holding packaging together, polyisobutylene plays a role in ensuring durability and performance.

A Brief History and Development

Polyisobutylene was first developed in the early 20th century as part of efforts to create synthetic rubbers and plastics. Its unique properties quickly caught the attention of manufacturers looking for durable materials. By the mid-1900s, PIB became a staple ingredient in adhesives, lubricants, and sealants. Over time, advances in high-activity PIB production have made it even more effective and adaptable, further expanding its use across industries.

Global Polyisobutylene (PIB) Manufacturers and Production Capacities

Polyisobutylene (PIB) is produced by a limited number of large global manufacturers. Total worldwide capacity is estimated at 1.4–1.48 million tons per year, with Asia (China, South Korea, Saudi Arabia, India, Japan) playing an increasingly important role in new capacity additions.

| Manufacturer | Country / Region | Approx. Capacity (tons/year) | Notes & Highlights |

|---|---|---|---|

| ENEOS (JX Nippon Oil & Gas) | Japan / Asia-Pacific | ~70,000 (mid-MW PIB) | Strong in mid-molecular-weight PIB |

| BASF SE | Germany / Global | ~55,000 (mid-MW PIB) | Broad product portfolio, global supply |

| Daelim Industrial | South Korea & Saudi Arabia | 80,000 (Saudi JV) + 250,000 (Yeosu, Korea) | One of the largest PIB bases worldwide |

| Kothari Chemicals | India | Expanding capacity (not disclosed) | Largest PIB producer in India |

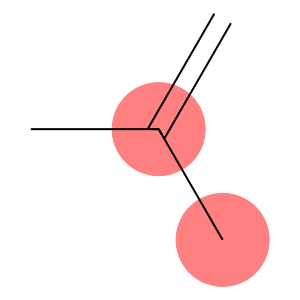

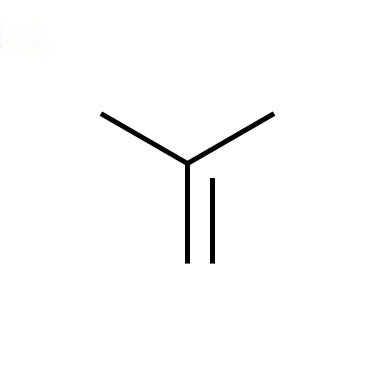

How is Polyisobutylene Made?

The Production Process Explained

The creation of polyisobutylene begins with the polymerization of isobutylene gas. This process takes place under controlled conditions using specialized catalysts. The result is a polymer chain that forms a rubbery, elastic material.

Manufacturers carefully control the molecular weight of the final product, as this determines whether PIB will be thick and sticky, like a glue, or soft and elastic, like a sealant.

High-Activity PIB vs. Conventional PIB

One key development in PIB technology is the rise of high-activity polyisobutylene. This version features more reactive sites on its molecular chain, making it especially useful for creating advanced lubricant additives like PIBSA (polyisobutylene succinic anhydride) and PIBSI (polyisobutylene succinimide).

These additives improve engine performance by reducing deposits, keeping engines clean, and extending oil life.

What is Polyisobutylene Used For?

Automotive and Lubricant Applications

One of the most significant uses of polyisobutylene lies in the automotive sector. In engine oils, PIB is used both as a viscosity modifier and as a foundation for lubricant additives. It helps oils maintain thickness under high temperatures while ensuring smooth flow in cold conditions.

Polyisobutylene in Lubricant Additives

PIB serves as the backbone for advanced lubricant additives, such as dispersants and detergents. These prevent sludge and deposit buildup in engines, allowing vehicles to run longer and more efficiently.

The Role of PIBSA and PIBSI in Engines

PIBSA (polyisobutylene succinic anhydride): Formed by reacting PIB with maleic anhydride, it’s a building block for dispersants.

PIBSI (polyisobutylene succinimide): A derivative of PIBSA, widely used ashless dispersants in engine oils to keep particles suspended and prevent wear.

Together, these compounds ensure that oils don’t just lubricate but also clean and protect.

Packaging, Adhesives, and Sealants

Beyond automotive applications, polyisobutylene plays a vital role in packaging and adhesives. Its sticky, elastic nature makes it ideal for creating pressure-sensitive adhesives used in tapes and labels. In sealants, it provides excellent flexibility and weather resistance, ensuring long-lasting bonds in construction and packaging industries.

One common example is butyl tape, which relies heavily on PIB to deliver airtight and waterproof sealing. This makes it useful in roofing, windows, and even food packaging, where protecting freshness is essential.

Everyday Consumer Products

You may not realize it, but PIB is present in everyday items:

Sealants for windows and tires – ensuring durability against weather and leaks.

Cosmetic products – sometimes used as a binder or thickener.

This quiet but essential role in consumer goods shows how deeply integrated polyisobutylene is in modern life.

Advantages of Polyisobutylene

Performance Benefits

Polyisobutylene stands out for several key reasons:

Elasticity: It stretches and returns to shape, ideal for adhesives and sealants.

Chemical resistance: Resists acids, bases, and oxidation.

Weather durability: Withstands sunlight, ozone, and temperature changes.

Low gas permeability: Keeps oxygen and moisture out, making it excellent for packaging.

These traits explain why manufacturers across diverse industries choose PIB as a dependable material.

Safety and Environmental Aspects

While PIB itself is considered stable and safe, like many industrial polymers, it requires responsible manufacturing and handling. Recycling opportunities exist but are still limited. Some manufacturers are working toward more sustainable production, though polyisobutylene is already valued for its durability, which reduces waste by extending product life.

Frequently Asked Questions (FAQs)

1. What is polyisobutylene in simple terms?

Polyisobutylene is a synthetic rubber-like polymer used in lubricants, adhesives, sealants, and packaging for its elasticity and resistance to chemicals and weather.

2. How is polyisobutylene made?

It is produced by polymerizing isobutylene gas under controlled conditions with catalysts, creating a flexible, rubbery polymer.

3. What is polyisobutylene used for?

It’s used in engine lubricants, adhesive tapes, sealants, packaging materials, chewing gum, and medical closures.

4. What are PIBSA and PIBSI?

PIBSA is polyisobutylene succinic anhydride, used as a dispersant precursor in lubricants.

PIBSI is polyisobutylene succinimide, a detergent/dispersant that keeps engines clean.

5. Who are the main manufacturers of polyisobutylene?

Large global chemical companies produce PIB, offering various grades for lubricants, packaging, and adhesives. Many regional suppliers also specialize in tailored grades.

6. Why is high-activity PIB important?

High-activity PIB provides more reactive sites, making it essential for producing advanced lubricant additives that improve engine performance.

Previous page

Next page

Previous page

Next page

PRODUCTS CENTER

MORE BLOG

2025-08-18

2025-08-17

2025-08-15

2025-08-11

2025-08-09

CheMost

CheMost Additives CO.,LTD

ADDRESS: CheMost Additives CO.,LTD, Jinzhou city, Liaoning provice, China

To learn more about CheMost, please click the button to contact us anytime.

Get product catalogCopyright© 2025 CheMost Additives CO.,LTD

Website:300.cn jinzhou.300.cn | SEO | Privacy Policy